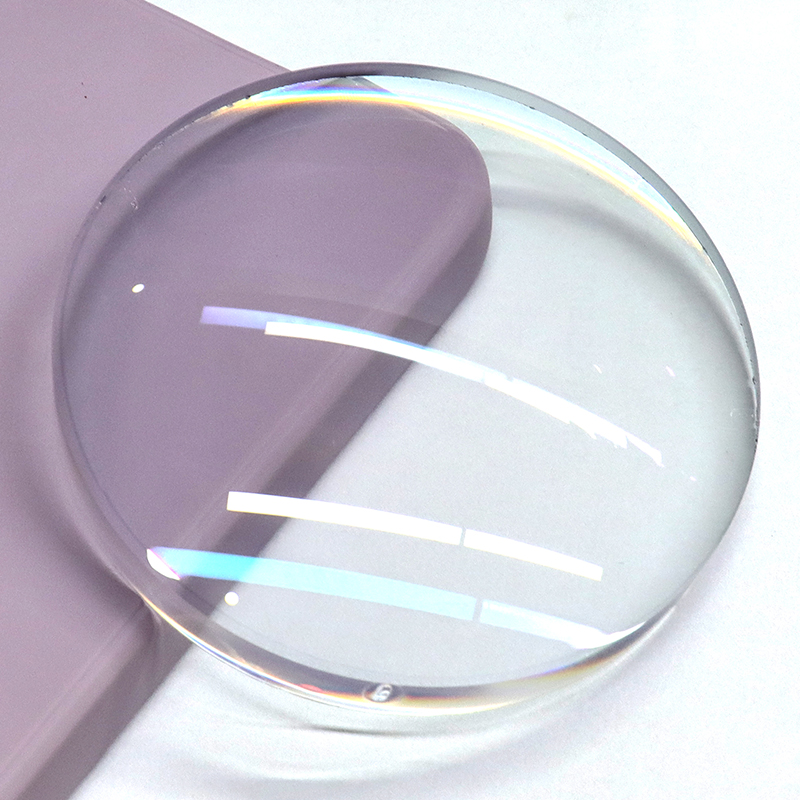

SETO 1.67 Semi-Finished Single Vision Lens

Specification

| 1.67 semi-finished optical lens | |

| Model: | 1.67 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Bending | 50B/200B/400B/600B/800B |

| Function | semi-finished |

| Lenses Color | Clear |

| Refractive Index: | 1.67 |

| Diameter: | 70/75 |

| Abbe Value: | 32 |

| Specific Gravity: | 1.35 |

| Transmittance: | >97% |

| Coating Choice: | UC/HC/HMC |

| Coating color | Green |

Product Features

1)The advantages of the 1.67 Index

①Lighter weight and thinner thickness, up to 50% thinner and 35% lighter than other lenses

②In the plus range, aspherical lens is up to 20% lighter and thinner than spherical lens

③Aspheric surface design for outstanding visual quality

④Flatter front curvature than non-aspheric or non-atoric lenses

⑤Eyes are less magnified than with traditional lenses

⑥High resistance to breakage (very suitable for sports and children’s spectacles)

⑦Full protection against UV rays

⑧Available with blue cut and photochromic lens

2)The definition of semi finished lens

①Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient's prescription. Different prescription powers request for different semi-finished lens types or base curves.

②The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or "curing" of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

3)What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory