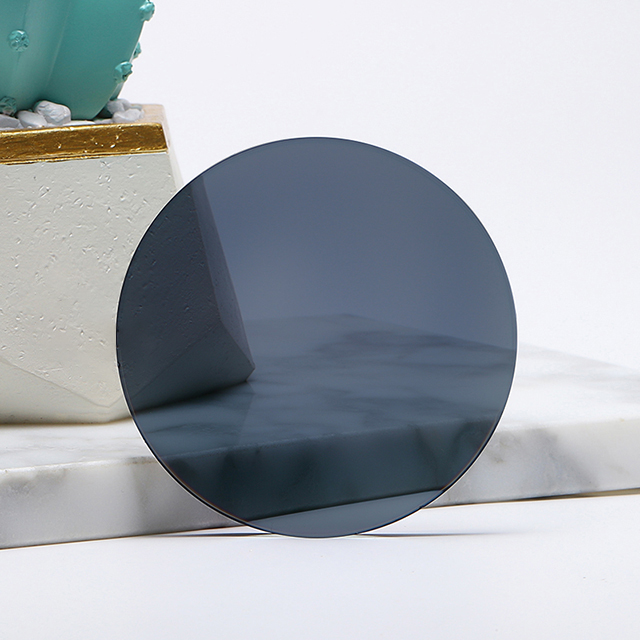

SETO 1.67 Photochromic Lens SHMC

Specification

| 1.67 photochromic shmc optical lens | |

| Model: | 1.67 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

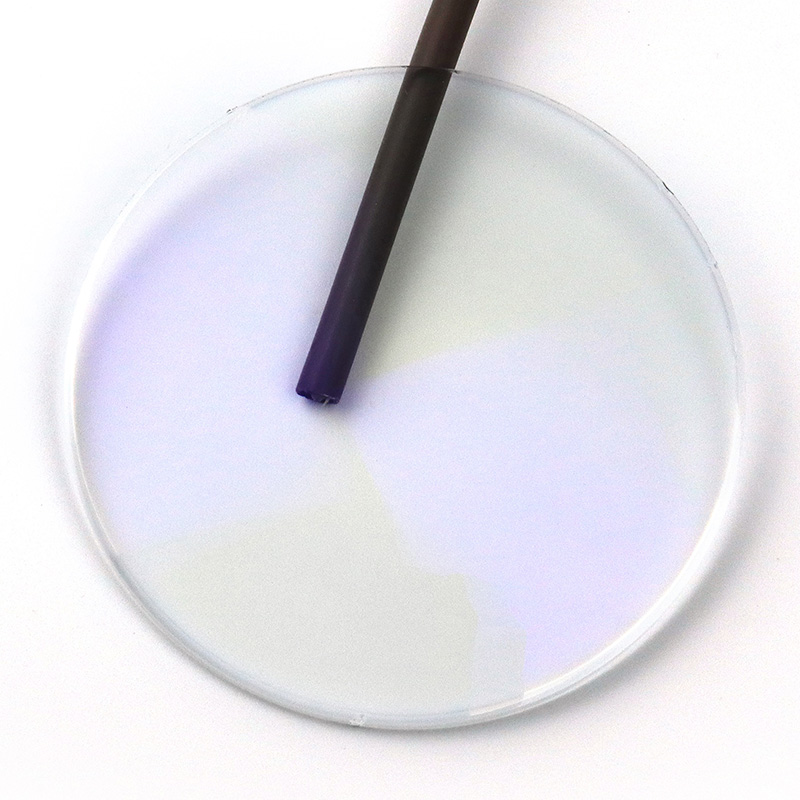

| Lenses Color: | Clear |

| Refractive Index: | 1.67 |

| Diameter: | 75/70/65 mm |

| Function: | photochromic |

| Abbe Value: | 32 |

| Specific Gravity: | 1.35 |

| Coating Choice: | HMC/SHMC |

| Coating color | Green |

| Power Range: | Sph:0.00 ~-12.00; +0.25 ~ +6.00; Cyl:0.00~ -4.00 |

Product Features

1)What is spin coating?

Spin coating is a procedure used to deposit uniform thin films onto flat substrates. Usually a small amount of coating material is applied on the center of the substrate, which is either spinning at low speed or not spinning at all. The substrate is then rotated at speed up to 10,000 rpm to spread the coating material by centrifugal force. A machine used for spin coating is called a spin coater, or simply spinner.

Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates. The higher the angular speed of spinning, the thinner the film. The thickness of the film also depends on the viscosity and concentration of the solution, and the solvent. Pioneering theoretical analysis of spin coating was undertaken by Emslie et al., and has been extended by many subsequent authors (including Wilson et al., who studied the rate of spreading in spin coating; and Danglad-Flores et al., who found a universal description to predict the deposited film thickness).

Spin coating is widely used in microfabrication of functional oxide layers on glass or single crystal substrates using sol-gel precursors, where it can be used to create uniform thin films with nanoscale thicknesses.[6] It is used intensively in photolithography, to deposit layers of photoresist about 1 micrometre thick. Photoresist is typically spun at 20 to 80 revolutions per second for 30 to 60 seconds. It is also widely used for the fabrication of planar photonic structures made of polymers.

One advantage to spin coating thin films is the uniformity of the film thickness. Owing to self-leveling, thicknesses do not vary more than 1%. However, spin coating thicker films of polymers and photoresists can result in relatively large edge beads whose planarization has physical limits.

2.Classification and principle of photochromic lens

Photochromic lens according to the lens discoloration parts are divided into photochromic lens (referred to as "base change ") and membrance layer discoloration lens (referred to as" film change ") two kinds.

The substrate photochromic lens is added a chemical substance of silver halide in the lens substrate. Through the ionic reaction of silver halide, it is decomposed into silver and halide to color the lens under strong light stimulation. After the light becomes weak, it is combined into silver halide so the color becomes lighter. This technique is often used for glass photochroimc lens.

Film change lens is specially treated in lens coating process. For example, spiropyran compounds are used for high-speed spin coating on the surface of the lens. According to the intensity of light and ultraviolet light, the molecular structure itself can be switched on and off to achieve the effect of passing or blocking light.

3. Coating Choice?

As 1.67 photochromic lens, super hydrophobic coating is the only coating choice for it.

Super hydrophobic coating also name crazil coating, can make the lenses waterproof, antistatic, anti slip and oil resistance.

Generally speaking , super hydrophobic coating can exist 6~12 months.

Certification

Our Factory