SETO 1.60 Semi-Finished Blue Block Single Vision Lens

Specification

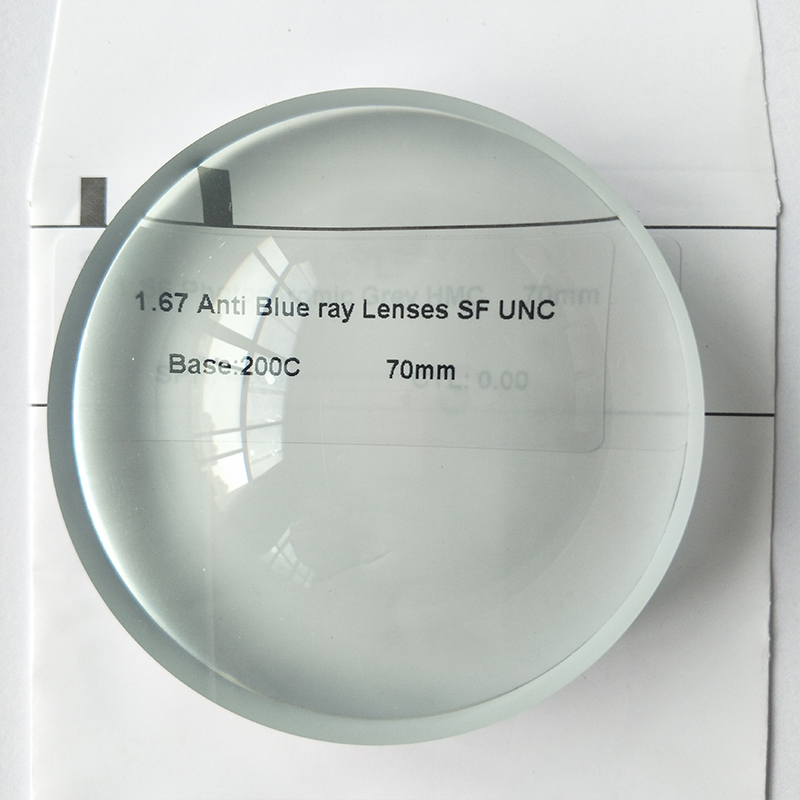

| 1.60 semi-finished blue block single vision optical lens | |

| Model: | 1.60 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

| Bending | 50B/200B/400B/600B/800B |

| Function | blue block & semi-finished |

| Lenses Color | Clear |

| Refractive Index: | 1.60 |

| Diameter: | 70/75 |

| Abbe Value: | 32 |

| Specific Gravity: | 1.26 |

| Transmittance: | >97% |

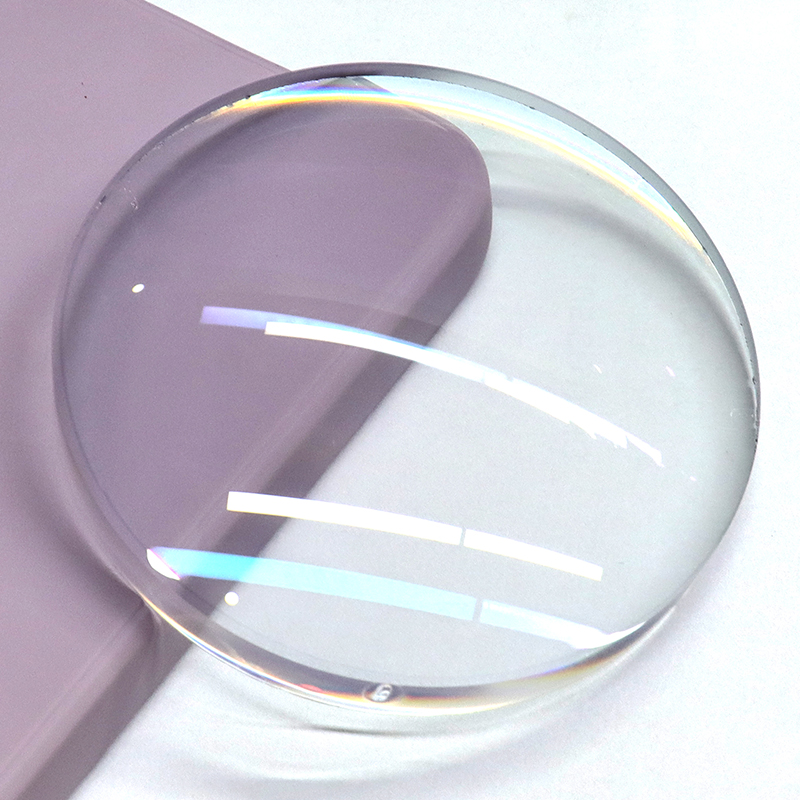

| Coating Choice: | UC/HC/HMC |

| Coating color | Green |

Product Features

1)What are the main anti-blue light technologies?

① film layer reflection technology: through the lens surface coating to reflect blue light, so as to achieve blue light blocking effect.

②substrate absorption technology: through blue light cut elements added in monomer of lens and blue light absorption so as to achieve blue light blocking effect.

③film layer reflection + substrate absorption: this is the latest anti blue light technology which combines the advantages of the above two technologies and doubles effect protection.

2)The definition of semi finished lens

①Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient's prescription. Different prescription powers request for different semi-finished lens types or base curves.

②The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or "curing" of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

3. What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory