SETO 1.60 Photochromic Lens SHMC

Specification

| 1.60 photochromic shmc optical lens | |

| Model: | 1.60 optical lens |

| Place of Origin: | Jiangsu, China |

| Brand: | SETO |

| Lenses Material: | Resin |

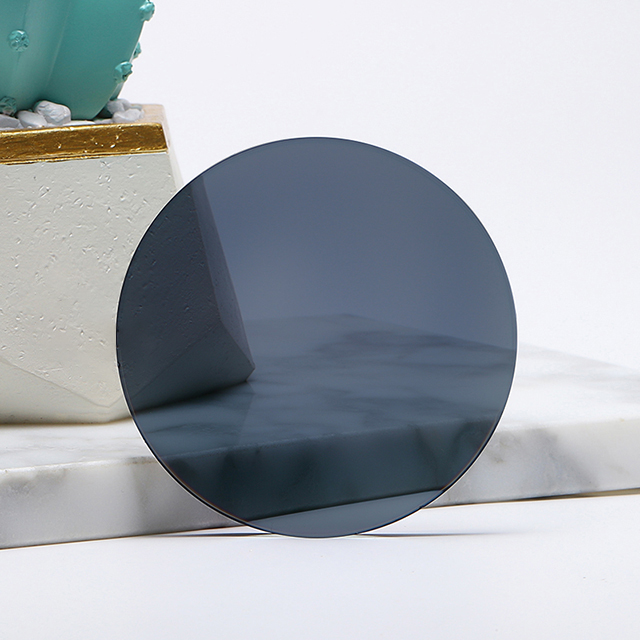

| Lenses Color: | Clear |

| Refractive Index: | 1.60 |

| Diameter: | 75/70/65 mm |

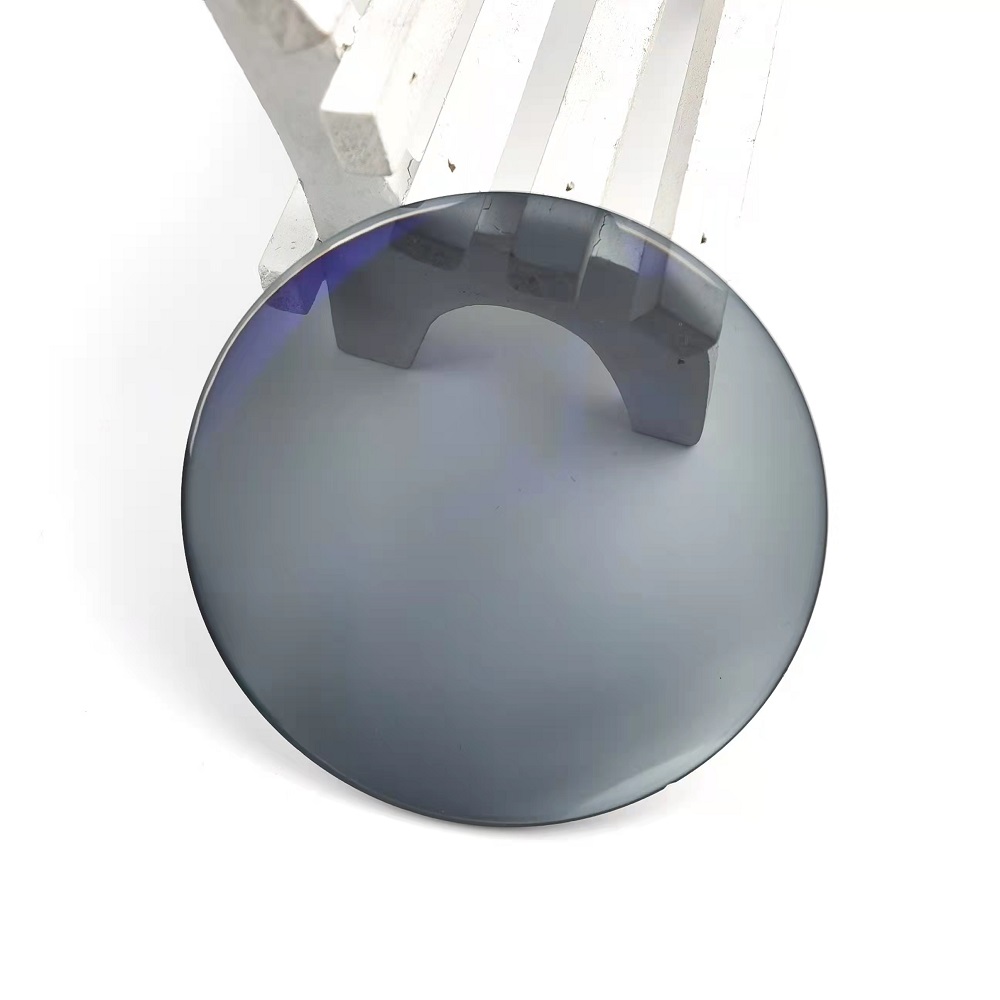

| Function: | photochromic |

| Abbe Value: | 32 |

| Specific Gravity: | 1.26 |

| Coating Choice: | HMC/SHMC |

| Coating color | Green |

| Power Range: | Sph:0.00 ~-10.00; +0.25 ~ +6.00; Cyl:0.00~ -4.00 |

Product Features

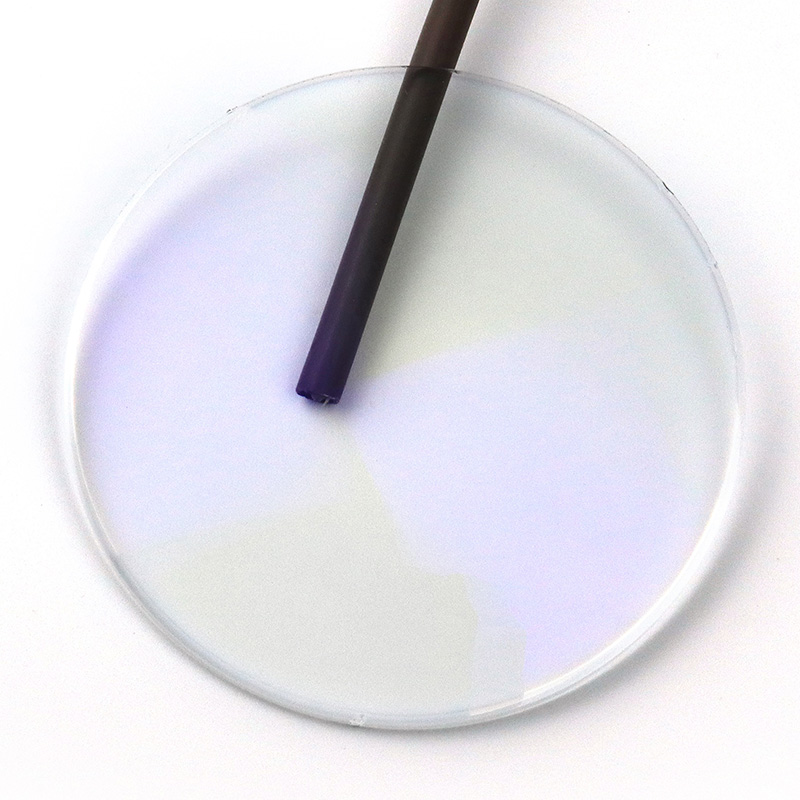

1) What is spin coating?

Spin coating is a procedure used to deposit uniform thin films onto flat substrates. Usually a small amount of coating material is applied on the center of the substrate, which is either spinning at low speed or not spinning at all. The substrate is then rotated at speed up to 10,000 rpm to spread the coating material by centrifugal force. A machine used for spin coating is called a spin coater, or simply spinner.

Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates. The higher the angular speed of spinning, the thinner the film. The thickness of the film also depends on the viscosity and concentration of the solution, and the solvent.[2] Pioneering theoretical analysis of spin coating was undertaken by Emslie et al., and has been extended by many subsequent authors (including Wilson et al.,[4] who studied the rate of spreading in spin coating; and Danglad-Flores et al.,[5] who found a universal description to predict the deposited film thickness).

Spin coating is widely used in microfabrication of functional oxide layers on glass or single crystal substrates using sol-gel precursors, where it can be used to create uniform thin films with nanoscale thicknesses.[6] It is used intensively in photolithography, to deposit layers of photoresist about 1 micrometre thick. Photoresist is typically spun at 20 to 80 revolutions per second for 30 to 60 seconds. It is also widely used for the fabrication of planar photonic structures made of polymers.

One advantage to spin coating thin films is the uniformity of the film thickness. Owing to self-leveling, thicknesses do not vary more than 1%. However, spin coating thicker films of polymers and photoresists can result in relatively large edge beads whose planarization has physical limits.

2) How Does Spin Coating Work?

This process works by carefully controlling the speed relative to various material properties of the solution. Viscosity is prime among these properties as it determines the resistance to uniform flow, which is vital in achieving a uniform surface finish. Spin coating is subsequently carried out across an extremely wide speed range, from as little as 500 revolutions per minute (rpm) to as much as 12,000 rpm – depending on the viscosity of the solution.

Viscosity is not the only material property of interest in spin coating, however. Surface tension may also affect the flow characteristics of the solution, while percent solids can impact the required thin film thickness to achieve specific end-use properties (i.e. electrical mobility). Spin coating is subsequently conducted with a full understanding of the relevant material properties, with plenty of adjustable parameters to suit distinct characteristics (flow, viscosity, wettability, etc.).

Spin coating can be carried out using either a static or dynamic start, each of which can be programmed for user-defined acceleration ramping and various spin speeds. It is also important to allow for fume exhaust periods and drying times as poor venting can result in optical flaws and non-uniformities. For example: Swirl patterns may indicate that the exhaust rate is too high for a solution that takes longer to dry. There is no one-size-fits-all solution when it comes to spin coating, and each process must be carried out with a holistic approach to the substrate and coating solution in question.

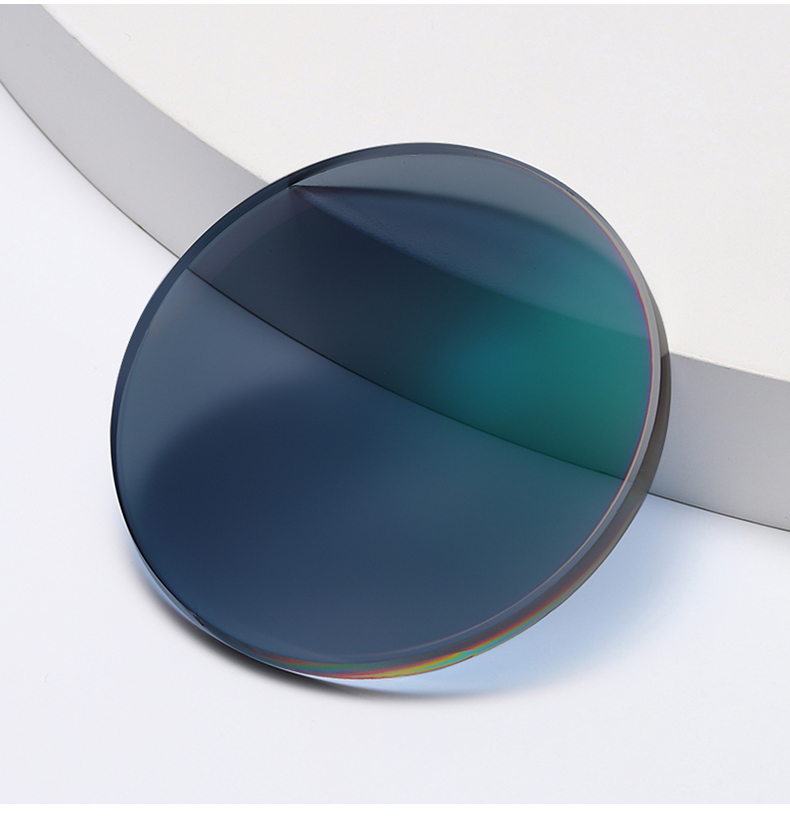

3) Coating Choice?

As 1.60 Photochromic Lens SHMC, super hydrophobic coating is the only coating choice for it.

Super hydrophobic coating also name crazil coating, can make the lenses waterproof, antistatic, anti slip and oil resistance.

Generally speaking , super hydrophobic coating can exist 6~12 months.

Certification

Our Factory