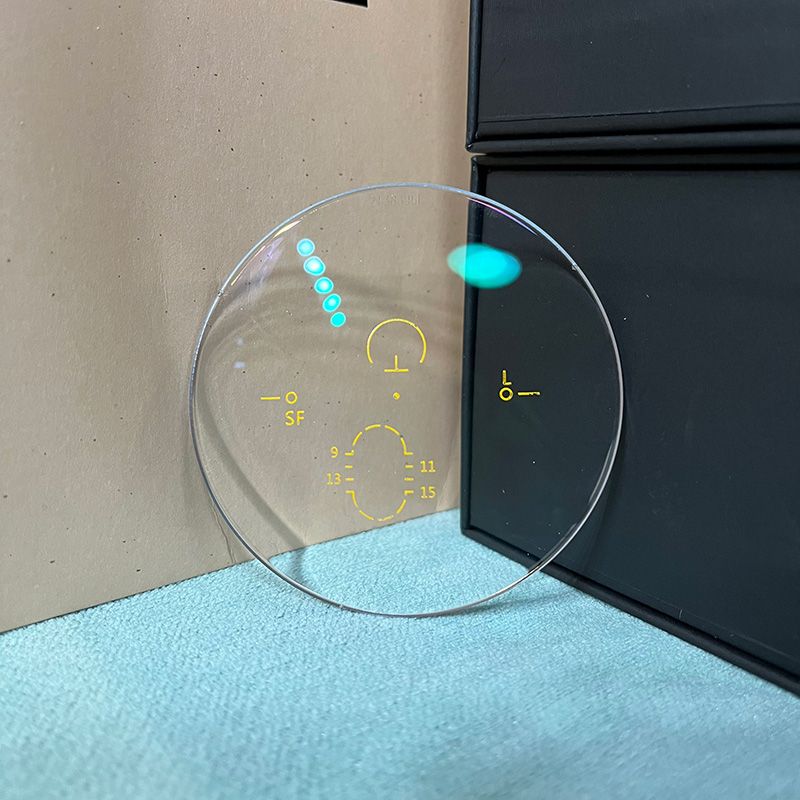

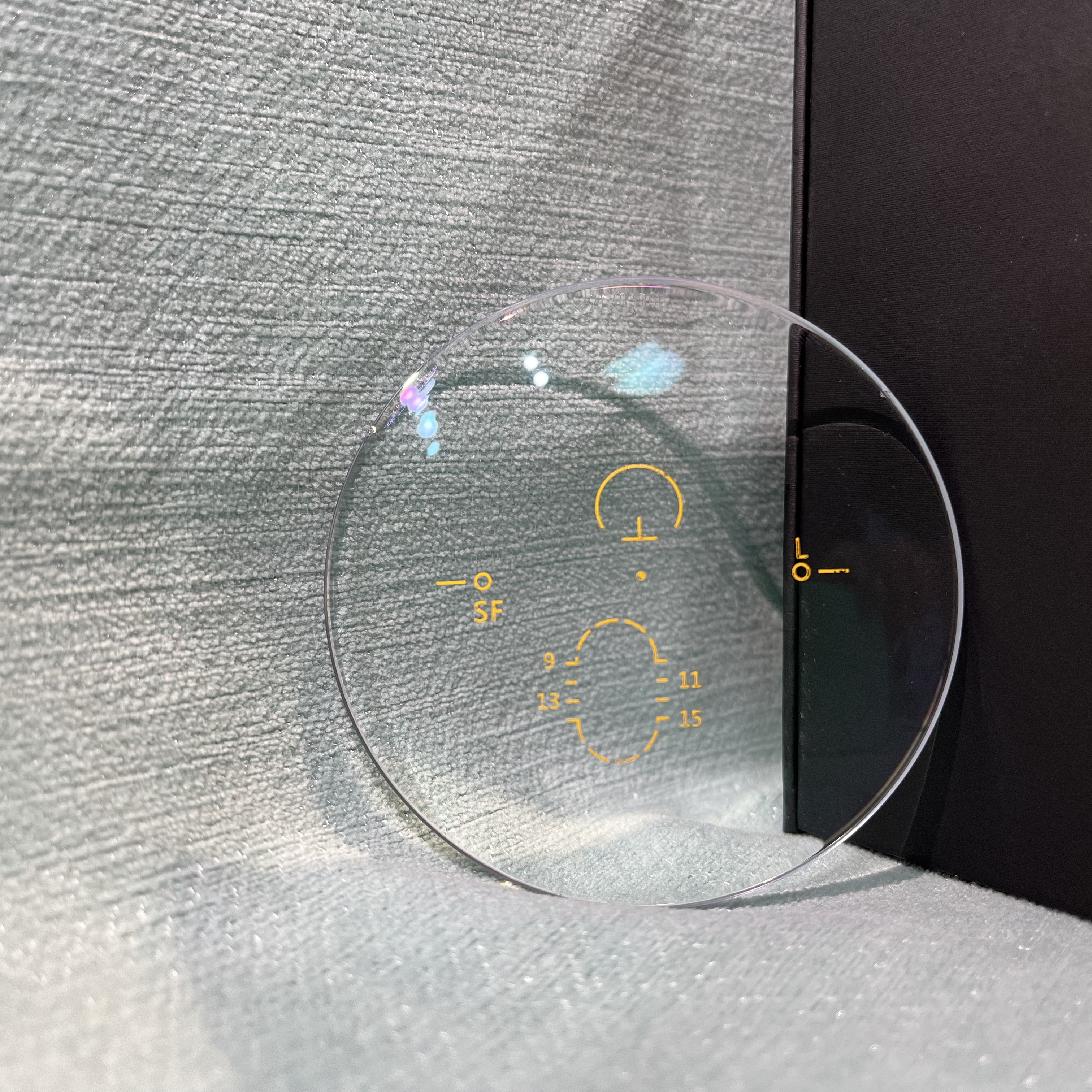

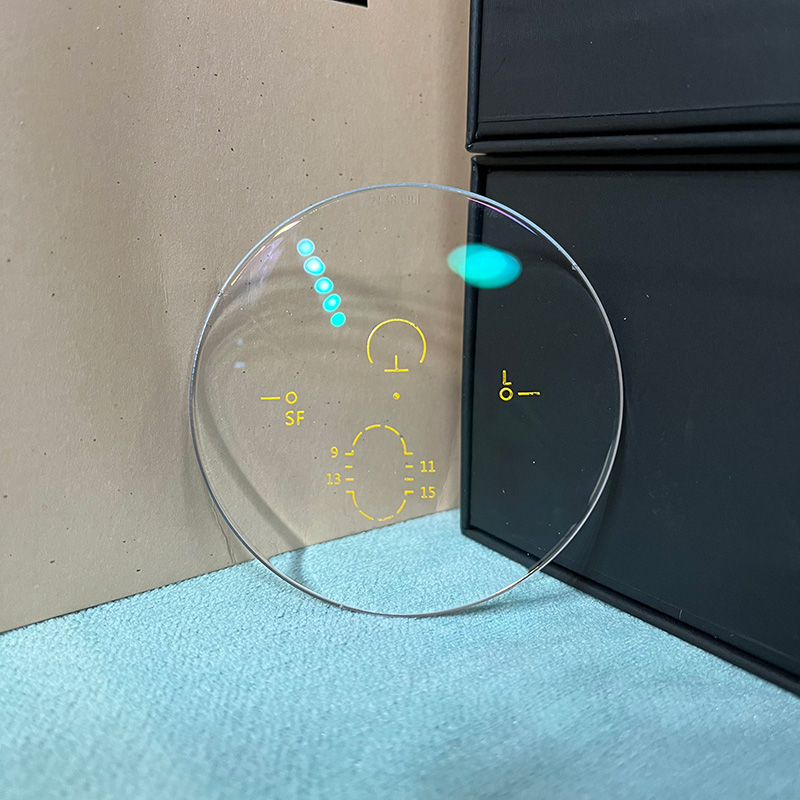

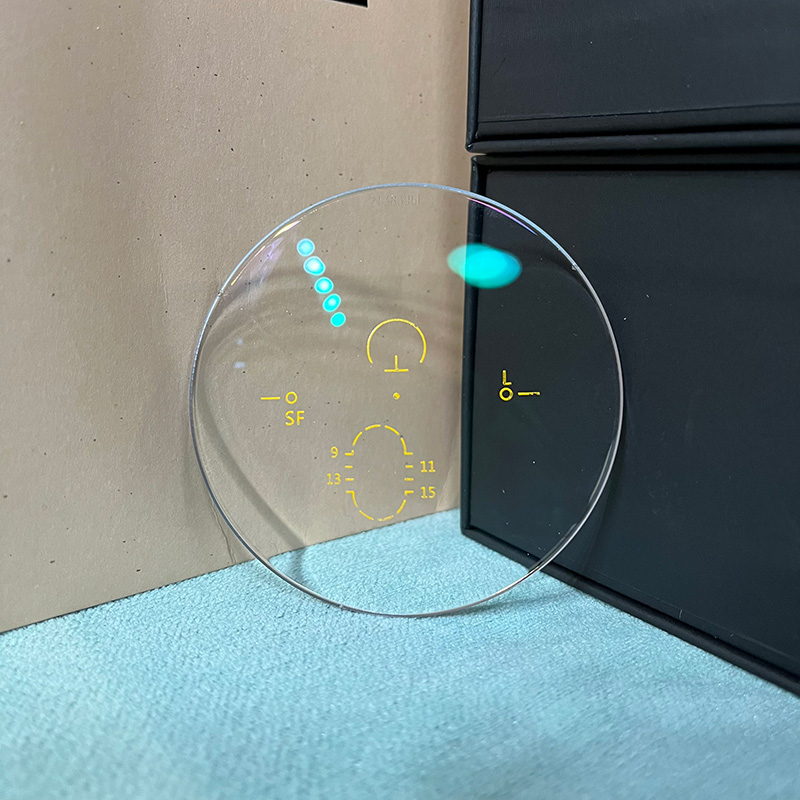

Opto Tech Office 14 Progressive Lenses

Specification

Enhanced Intermediate Zones for Different Purposes

| Prescribed | Dynamic Power Office Lens | |||

| Add. Power | -0.75 | -1.25 | -1.75 | -2.25 |

| 0.75 | infinity | |||

| 1.00 | 4.00 | |||

| 1.25 | 2.00 | infinity | ||

| 1.50 | 1.35 | 4.00 | ||

| 1.75 | 1.00 | 2.00 | infinity | |

| 2.00 | 0.80 | 1.35 | 4.00 | |

| 2.25 | 1.00 | 2.00 | infinity | |

| 2.50 | 0.80 | 1.35 | 4.00 | |

| 2.75 | 1.00 | 2.00 | ||

| 3.00 | 0.80 | 1.35 | ||

| 3.25 | 1.00 | |||

| 3.5 | 0.80 | |||

How to make freeform progressive ?

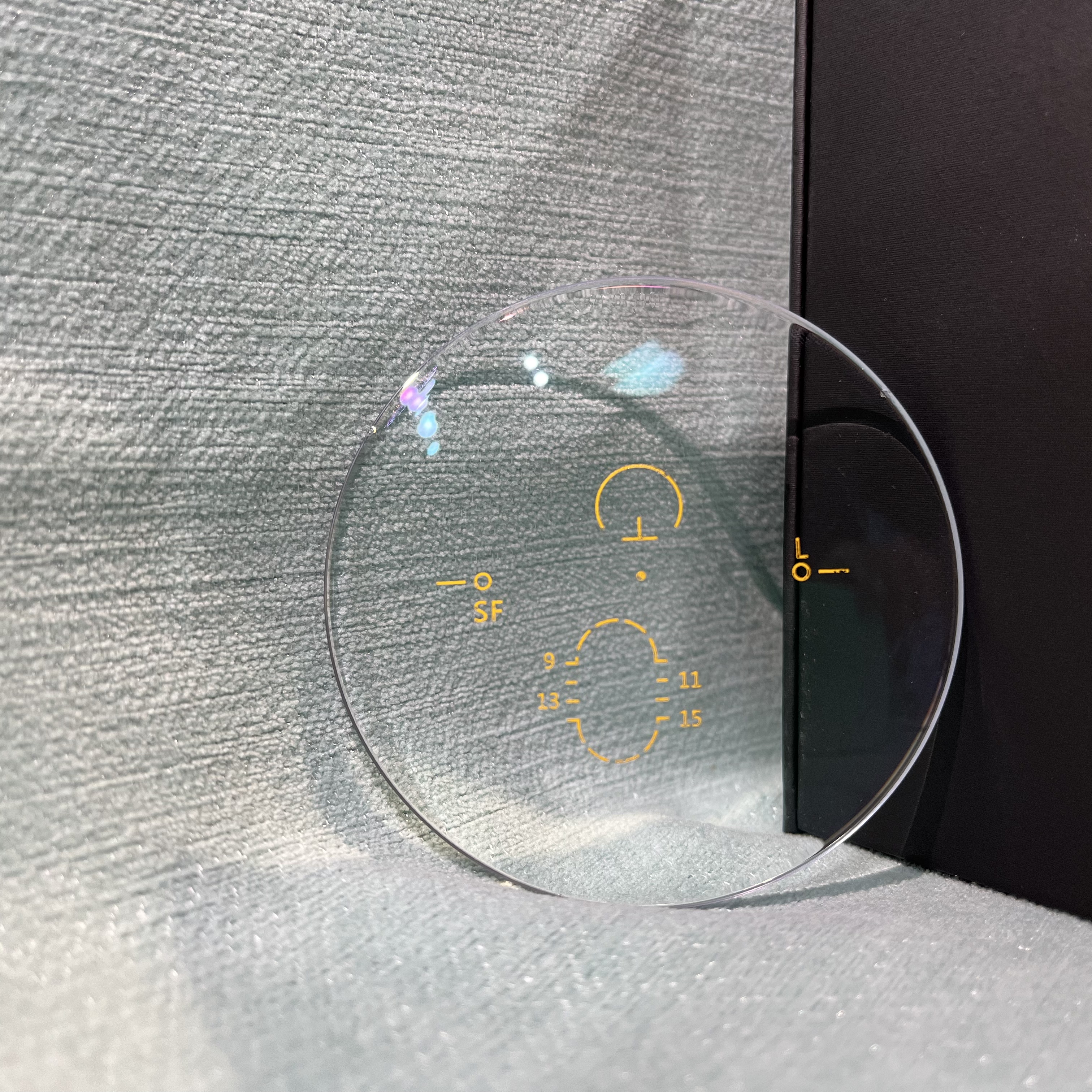

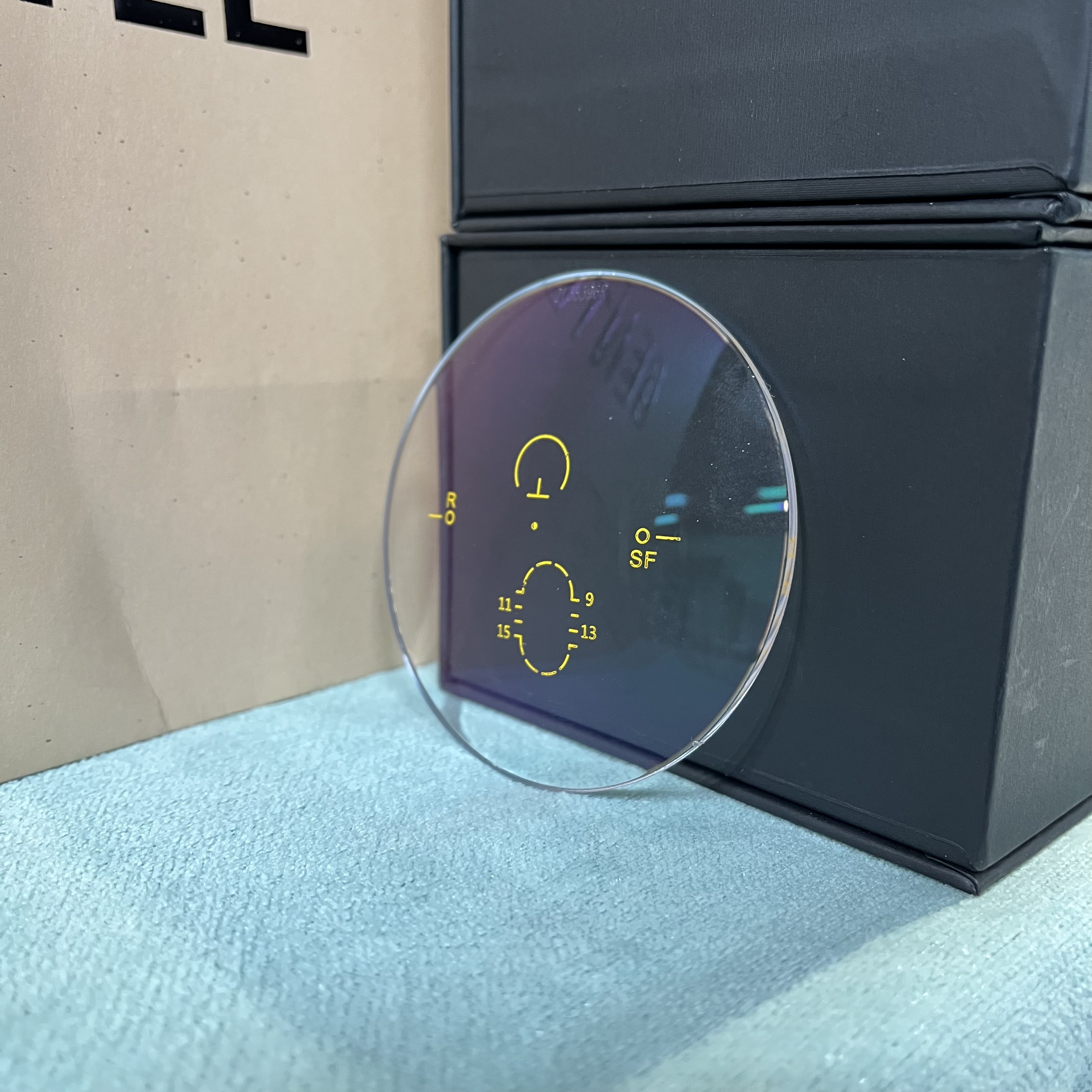

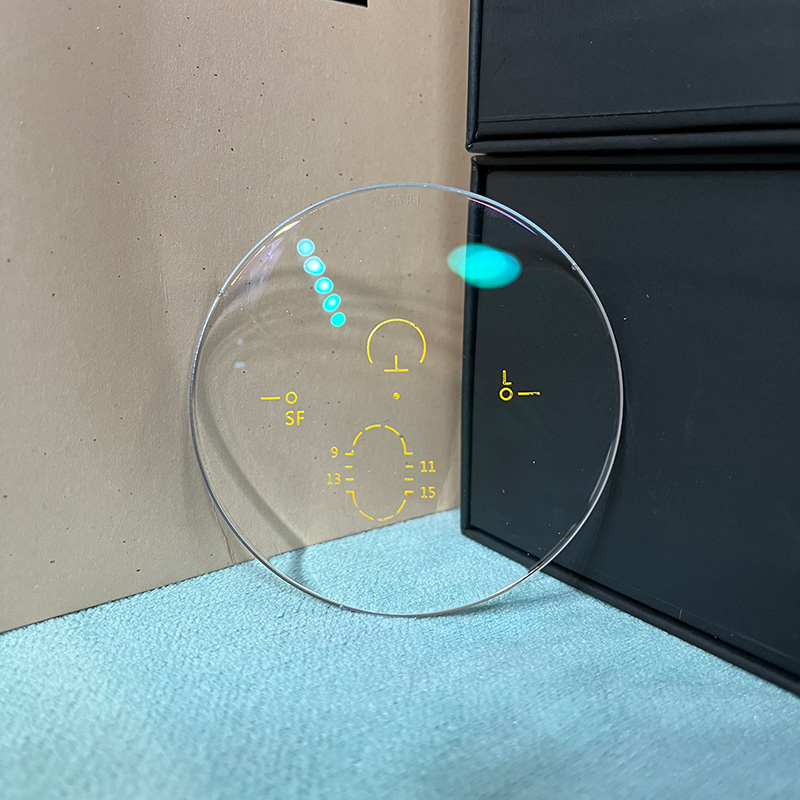

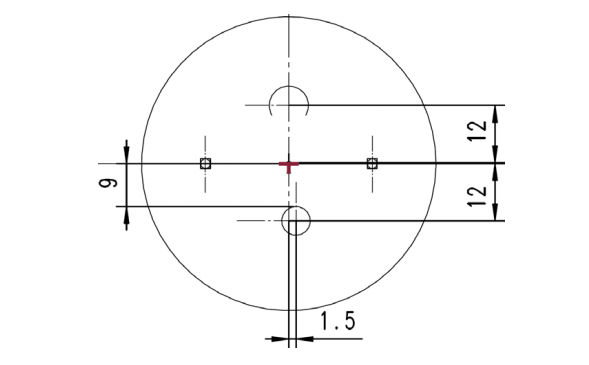

The freeform progressive lens uses the back surface freeform technology which places the progressive surface on the back of the lenses, providing you with a wider field of vision.

Freeform progressive lens is fabricated differently than any other type of lens design. The lens currently costs more than traditionally produced lens, but the visual benefits are apparent. Using proprietary software and computer numerically controlled (CNC) technology, the required patient specification can be very rapidly interpreted as the design criterion, which is then fed to high speed and precision freeform machinery. This consists of three dimensional diamond cutting spindles, which grind the highly complex lens surfaces to an accuracy of 0.01D. It is possible to grind either or both lens surfaces using this method. With the latest generation of varifocals, some manufacturers retained the moulded semi-finished blanks and use free-form technology to produce the optimum prescription surface.

Certification

Our Factory