Opto Tech HD Progressive Lenses

Design Characteristics

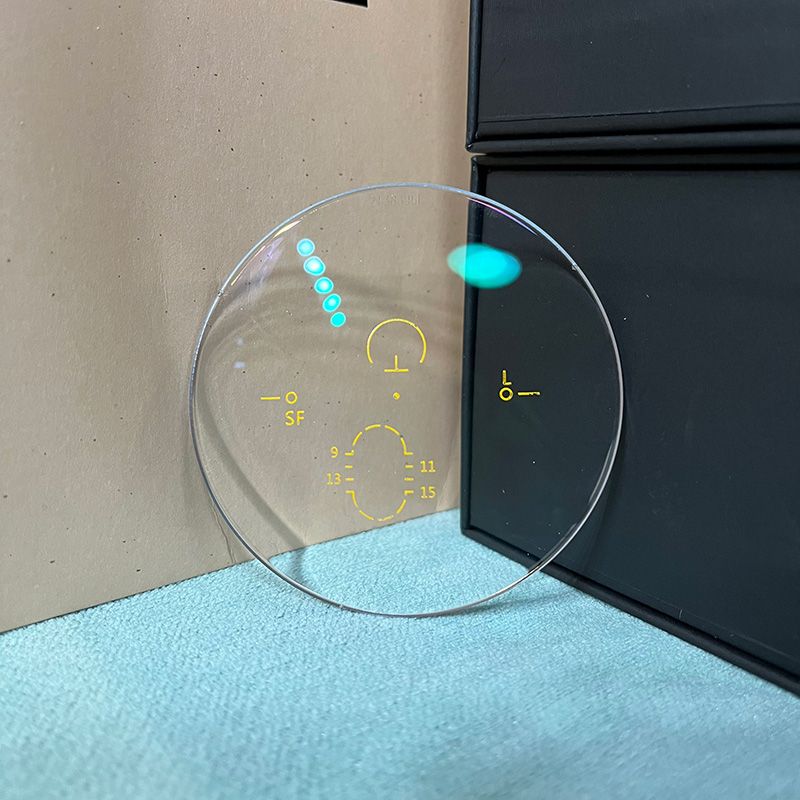

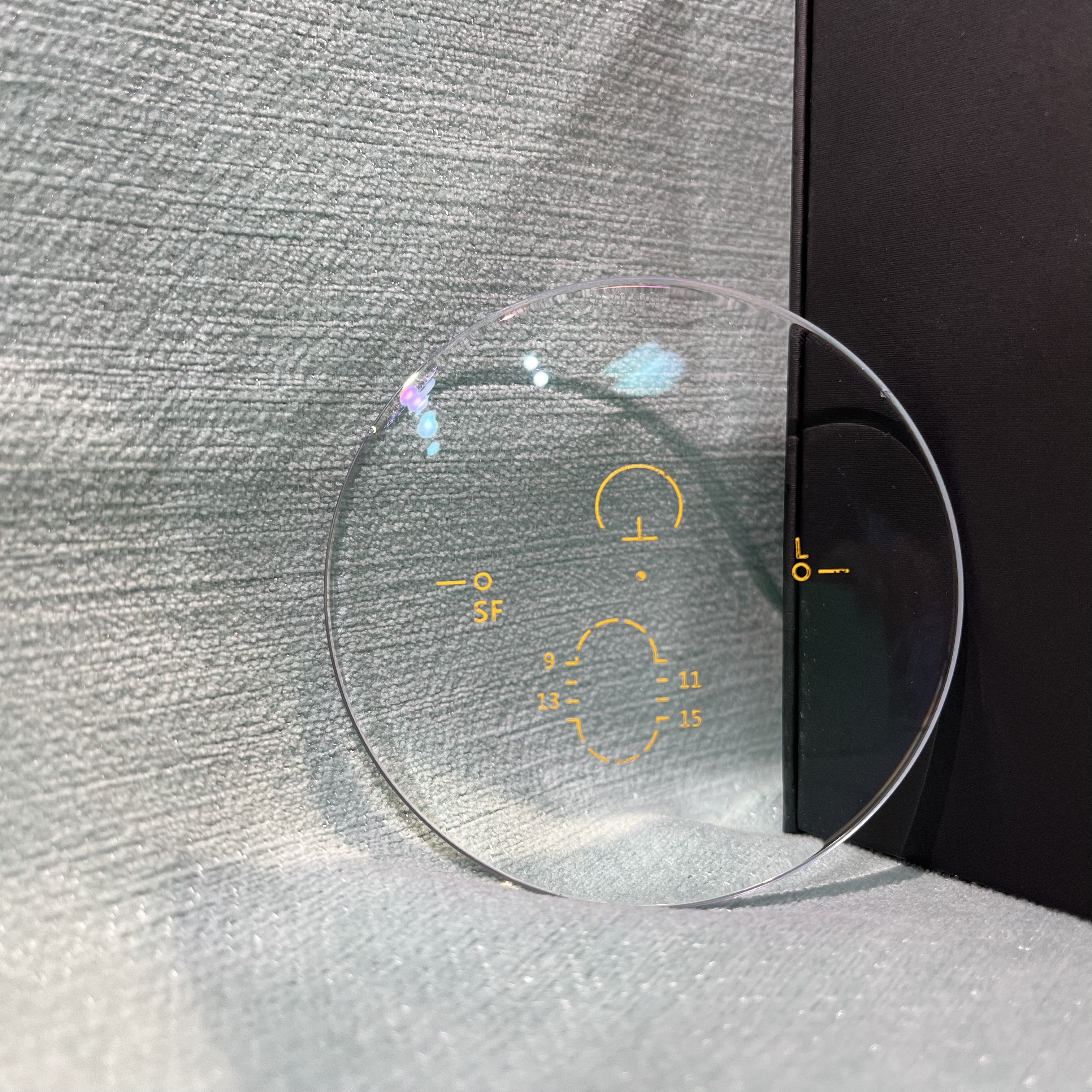

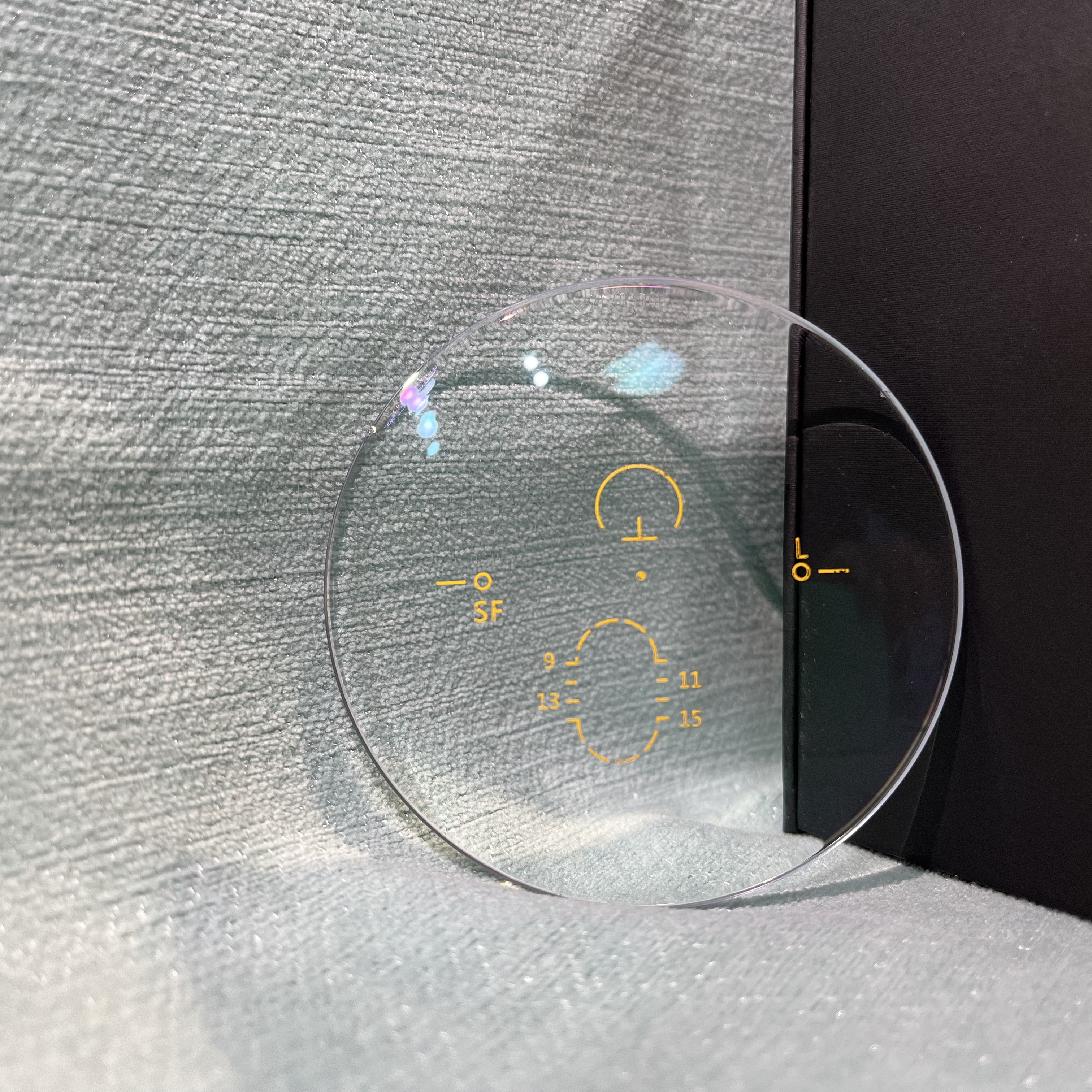

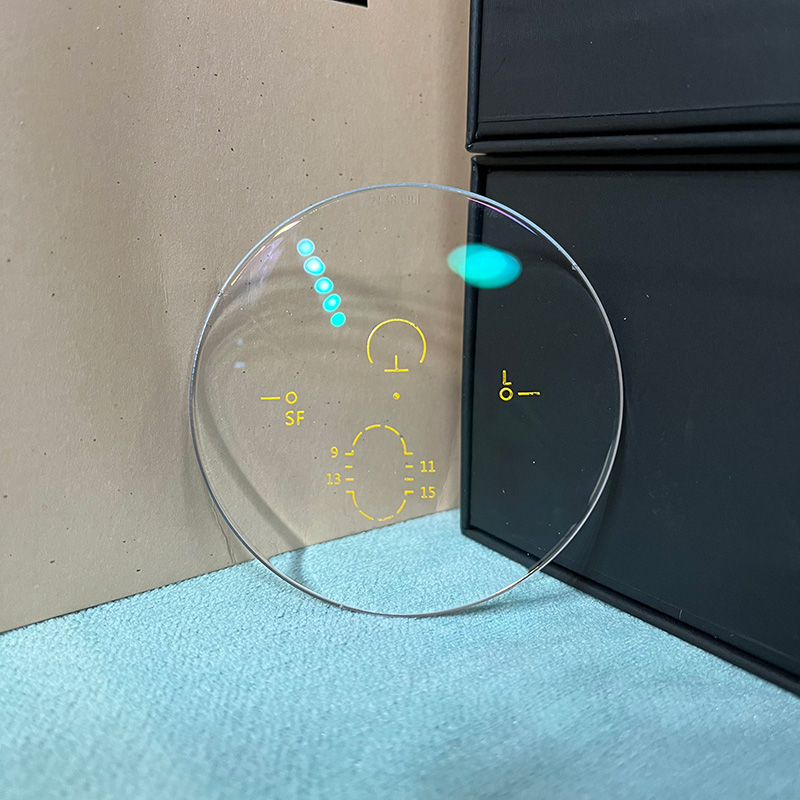

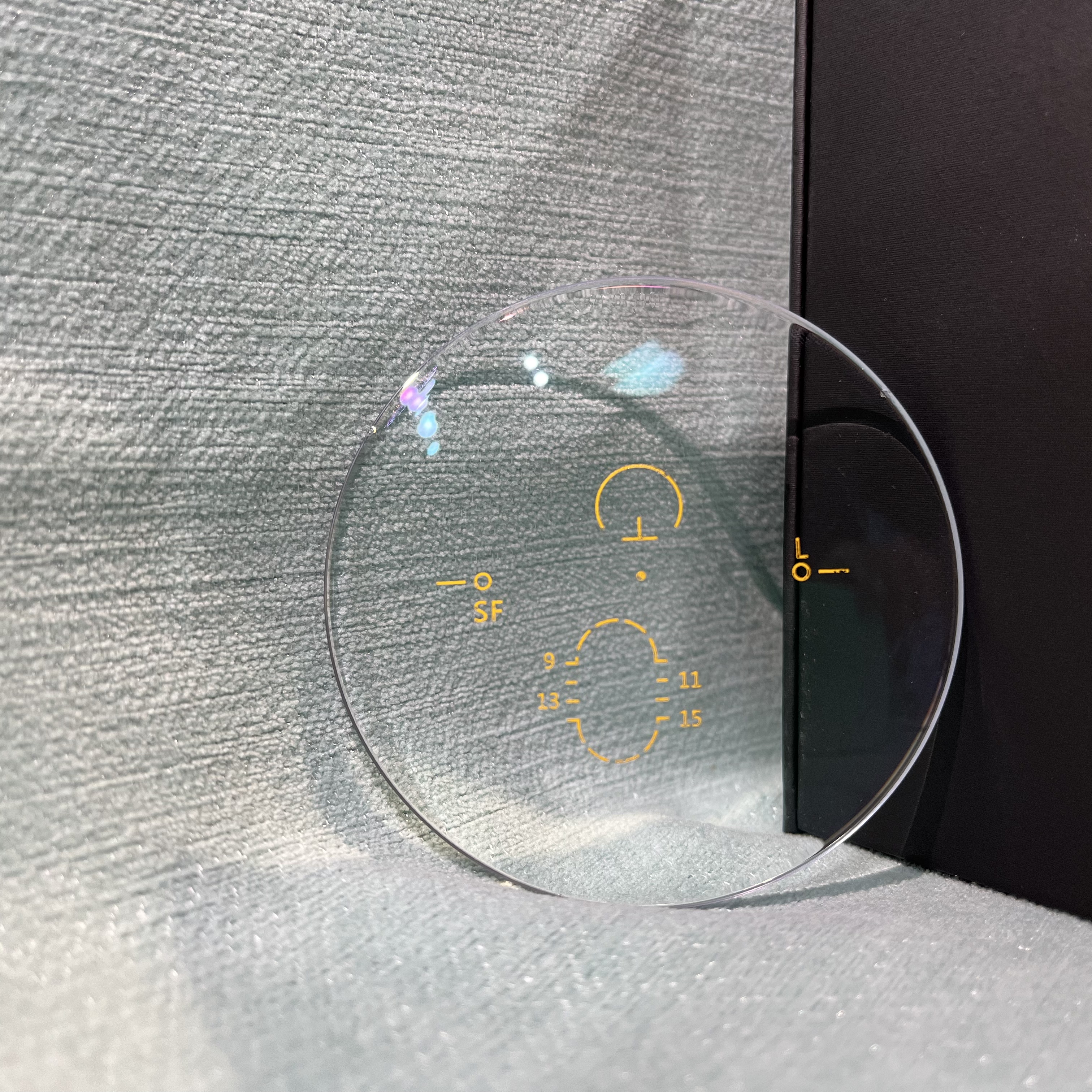

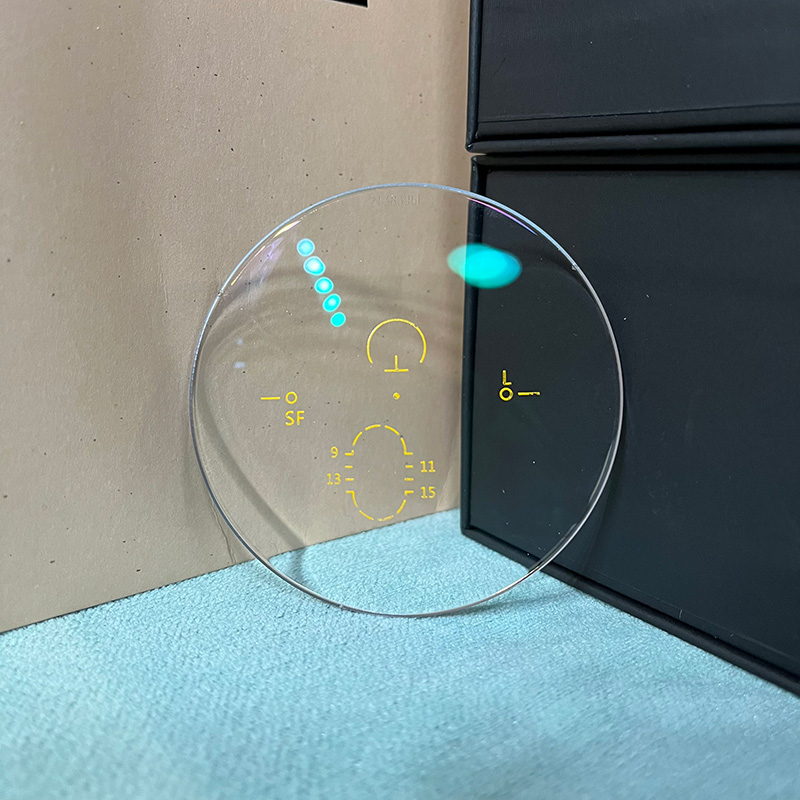

The Entry and Drive Design

| Corridor Length (CL) | 9 / 11 / 13 mm |

| Near Reference Point (NPy) | 12 / 14 / 16 mm |

| Minimum Fitting Height | 17 / 19 / 21 mm |

| Inset | 2.5 mm |

| Decentration | up to 10 mm at max. dia. 80 mm |

| Default Wrap | 5° |

| Default Tilt | 7° |

| Back Vertex | 13 mm |

| Customize | Yes |

| Wrap Support | Yes |

| Atorical Optimization | Yes |

| Frameselection | Yes |

| Max. Diameter | 80 mm |

| Addition | 0.50 - 5.00 dpt. |

| Application | Drive;Outdoor |

Opto Tech

To develop a new progressive lens in a high quality level, extreme complex and powerful optimization programs are necessary.To simplify, you have to imagine that the optimization program looks for a surface which combines two different spheric surfaces (distance and near vision) as even as possible.It is important, that the areas for distance and near view are developed as comfortable as possible with all required optical properties. Also the transformed areas should be as smooth as possible, that means without big unwanted astigmatism. These punitive easy looking requirements are practically very difficult to solve. A surface has, at a normal size of 80 mm x 80 mm and a point distance of 1 mm, 6400 interpolation points. If now each individual point gets the freedom to move within 1 mm about 1 µm (0.001 mm) for the optimization, with 64001000 you have an incredible high number of possibilities. This complex optimization is based on the ray tracing technology.

What is the difference between HC, HMC and SHC?

| Hard coating | AR coating/Hard multi coating | Super hydrophobic coating |

| makes the uncoated lens hard and increases the abrasion resistance | increases the transmittance of the lens and reduces surface reflections | makes the lens waterproof, antistatic, anti slip and oil resistance |

Certification

Our Factory